Week 9

Title of Activity

Continue Programming from last week.

Objective

-Troubleshoot the program.

-Searching the solution in website arduino and forum.

Title of Activity

Continue Programming from last week.

Objective

-Searching the solution in website arduino and forum.

Content/Procedure

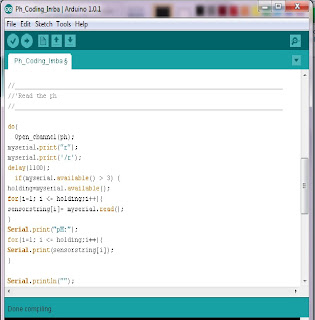

My previously problem is "a function-definition is not allowed here before }" that make strugglin to find the solution in their web support.

So, I find the related same problem with my problem. Then i try used that advice to fix my problem.

Still that have some error that can't be read. That error it detect "a function-definition is not allowed here before }". Try to do more research to counter my program in this week.

Conclusion

Some basic in writing a program because they are some command we should able to understand, if have no basic about programming it can cause your trouble and stuck.. For this problem i do more research and reading a arduino language style program.